ESD Protection with ERGO-line

ESD – Definition

ESD stands for electrostatic discharge. It describes the sudden transfer of electrical charge between two objects with different voltage levels. These charge differences often occur through friction. This process is known as triboelectric charging and it can leave people, tools, or materials electrically charged. When objects with different charge levels come close to each other, the charge equalizes in an instant. That moment of discharge is what we call ESD.

When working with sensitive electronic components, controlling this process is critical. Proper ESD protection prevents static build up on people and workplace equipment. The result is safer handling, fewer component failures, and more reliable processes throughout your operation.

ESD – Risks

The greatest ESD risk comes from people and their behavior, for example when electronic components are handled without protective clothing or proper training. Skin, hair, and clothing are especially prone to carrying high electrical charges. Because people easily pick up and carry static electricity, this creates a significant risk of electrostatic discharge.

Most people are familiar with the small shock felt when touching a door handle. This is a typical ESD event. However, humans usually only perceive electrostatic discharge at much higher levels, starting at around 3,000 volts. Sensitive electronic components can already be damaged or even completely destroyed at levels as low as 35 volts. As a result, many discharges go unnoticed, even though they cause real damage.

ERGO line ESD protected workstations safely dissipate existing charges to ground.

ESD – Business impact

In electronics manufacturing, industrial electronics, computer technology, telecommunications, automotive electronics, and many other production sectors, electrostatic discharge (ESD) is one of the most critical challenges. Especially problematic are quality issues that only become visible days, weeks, or even months after a product has been delivered to the customer.

These delayed failures can lead to customer complaints, increased repair and replacement costs, damage to your reputation, and ultimately the loss of orders and customers.

ESD – Protection standards

There are several international standards for electrostatic discharge (ESD), with DIN EN 61340-5-1 being the most important. This standard specifies, defines, and mandates measures to prevent ESD.

All ERGO-line ESD products are certified to this standard.

ESD – Workplace protection measures

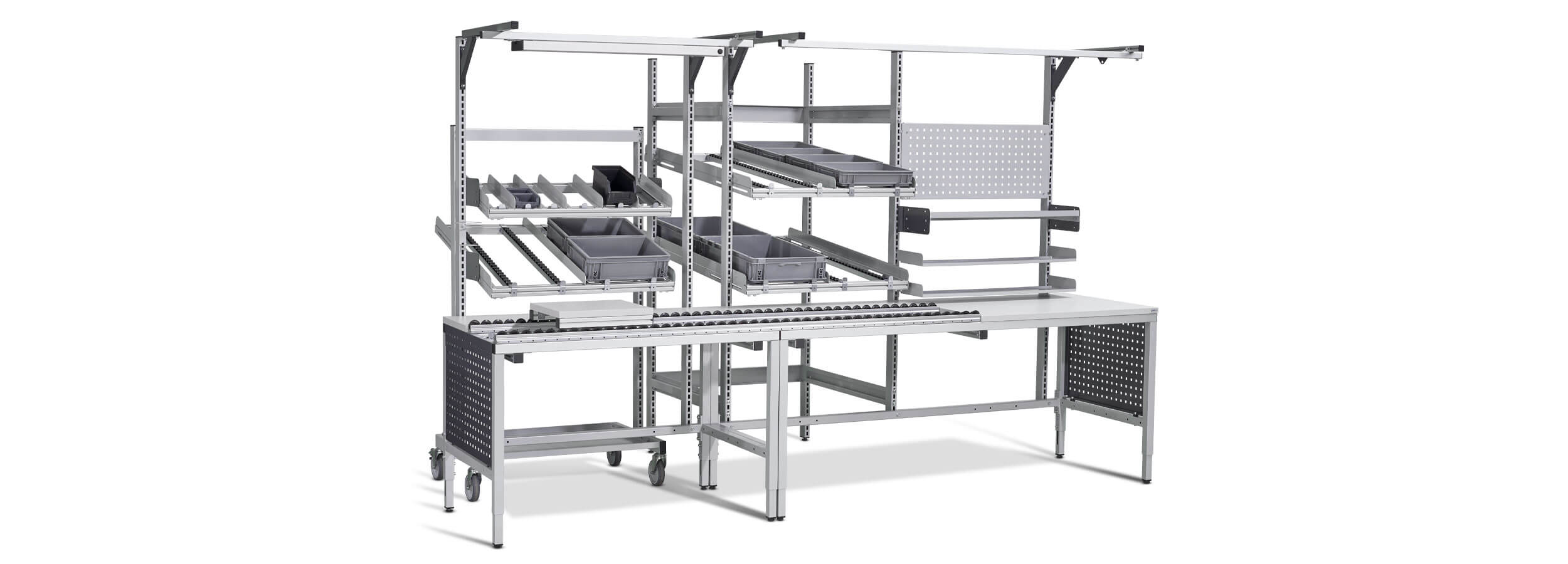

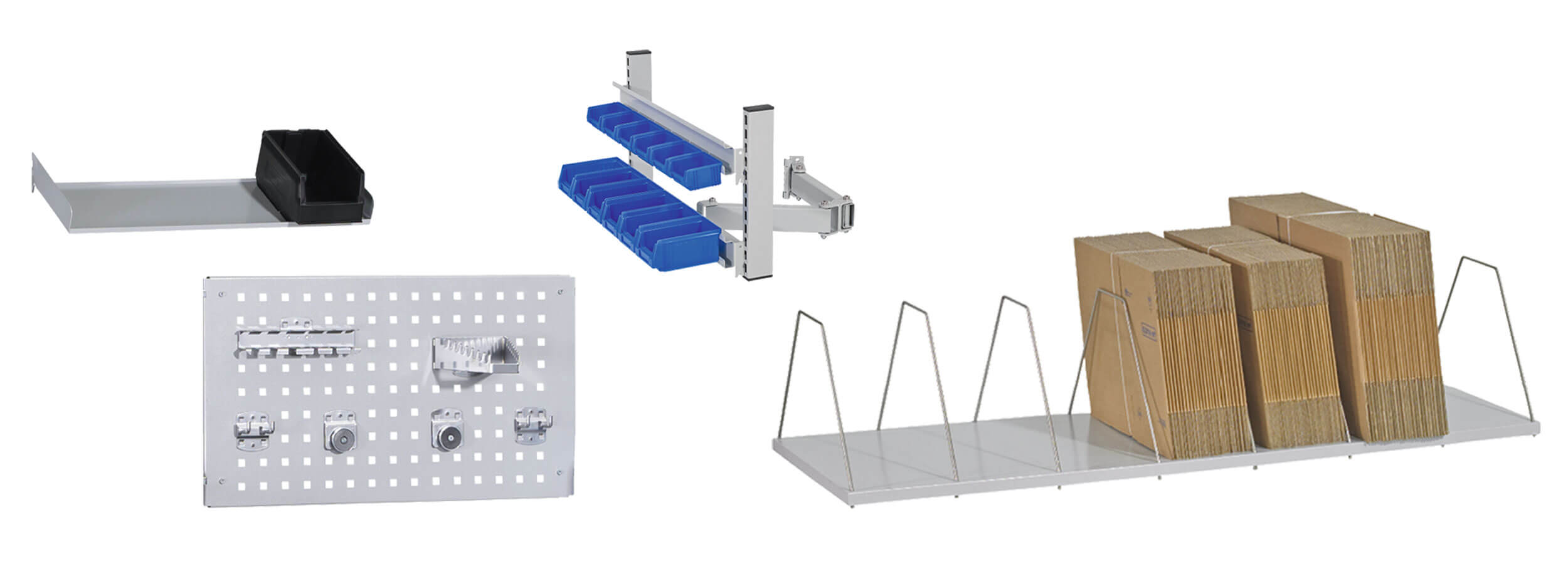

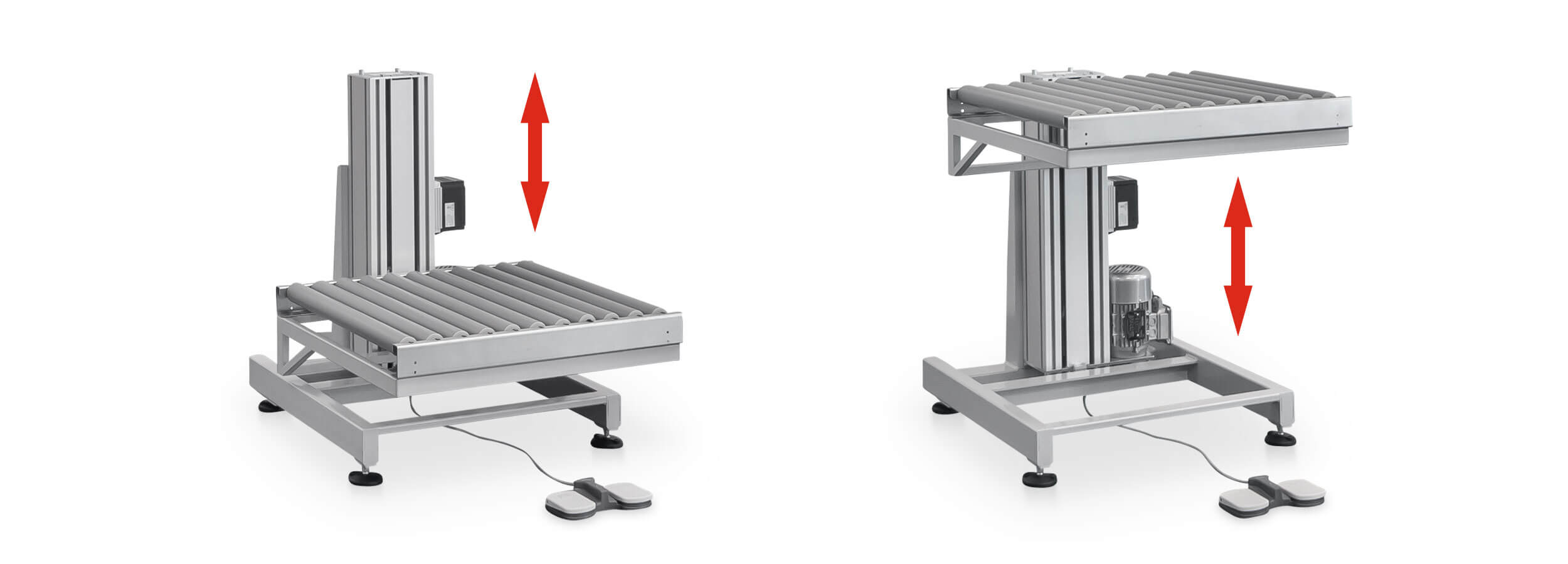

An optimal ESD workstation is part of a defined ESD protection zone where all materials are dissipative. This zone may include a single work surface, a dedicated area, an entire room, or even a whole building. Typical elements of such a zone include dissipative flooring, often implemented using specialized ESD floor mats. ESD furniture such as tables, work surfaces, chairs, and shelving is also essential.

Lighting is often overlooked. With ESD rated fixtures, both the housings and the louvers are made from dissipative materials or treated with appropriate coatings to prevent static buildup.

We’re happy to advise!

ERGO-line offers expert consulting for your ESD project.

All ERGO-line ESD products undergo a final outgoing inspection: before shipping, we test every ESD workstation for dissipative performance and approve it for delivery.

Get in Touch!

We provide non-binding advice and support you in implementing your project – for ergonomic solutions that suit you.

The ERGO-line team looks forward to meeting you!

More Articles