Workstation systemsApplications

Ergonomic workstation systems tailored precisely to your needs

Increased productivity, smoother processes, and a workstation that seamlessly adapts to your needs – whether it's a packing table, assembly table, ESD table, or assembly line. Direct from the manufacturer.

All workstation systems

Whether it’s manufacturing, material flow, or shipping: ERGO-line’s workstation systems cover the entire industrial supply chain. Our employees advise you at every stage of the production process and develop solutions tailored to your business.

Workstation systems for a smooth and productive working environment

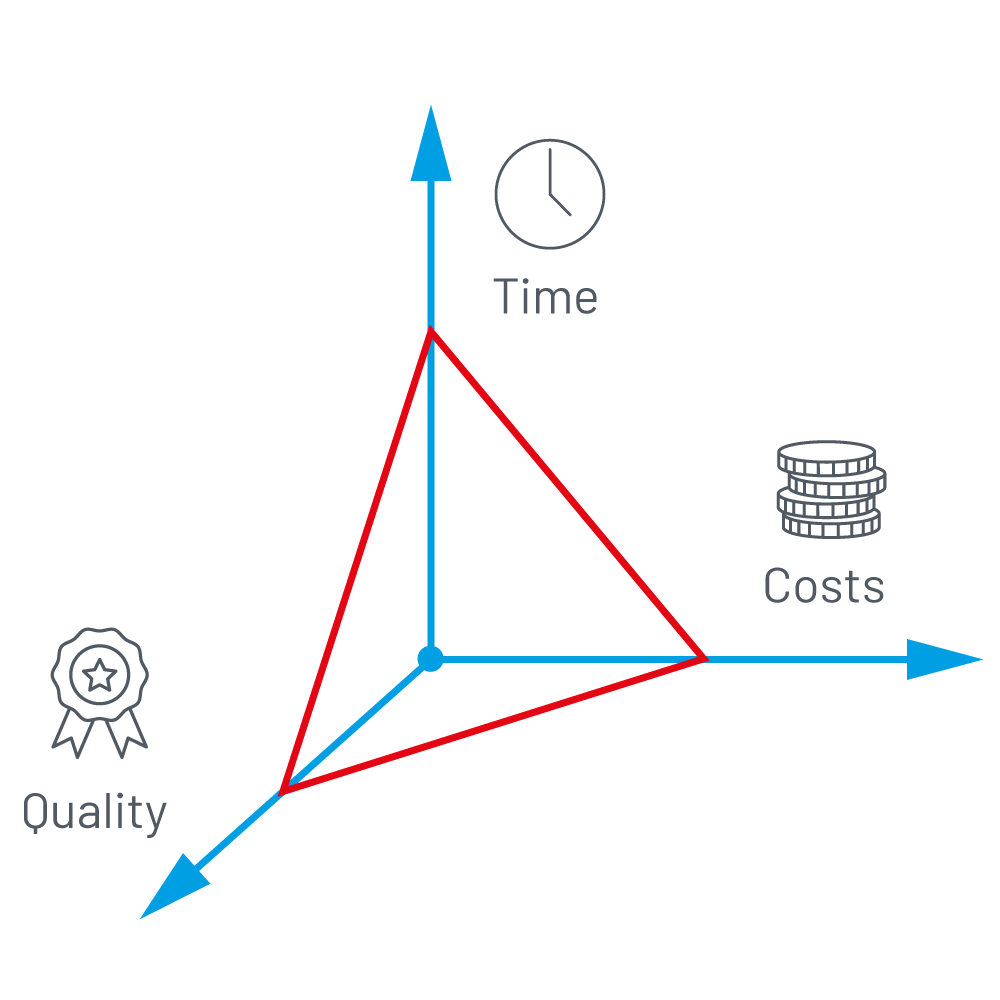

Time, cost, and quality are three important pillars in production. Modern manufacturing companies meet the classic requirement of delivering the required products to customers as quickly and cost-effectively as possible, while maintaining the best possible quality.

Taking these three factors into account, ERGO-line works closely with you to design the optimally equipped workstation for your company.

Packing tables

Speed up your packing processes with ergonomic packing tables

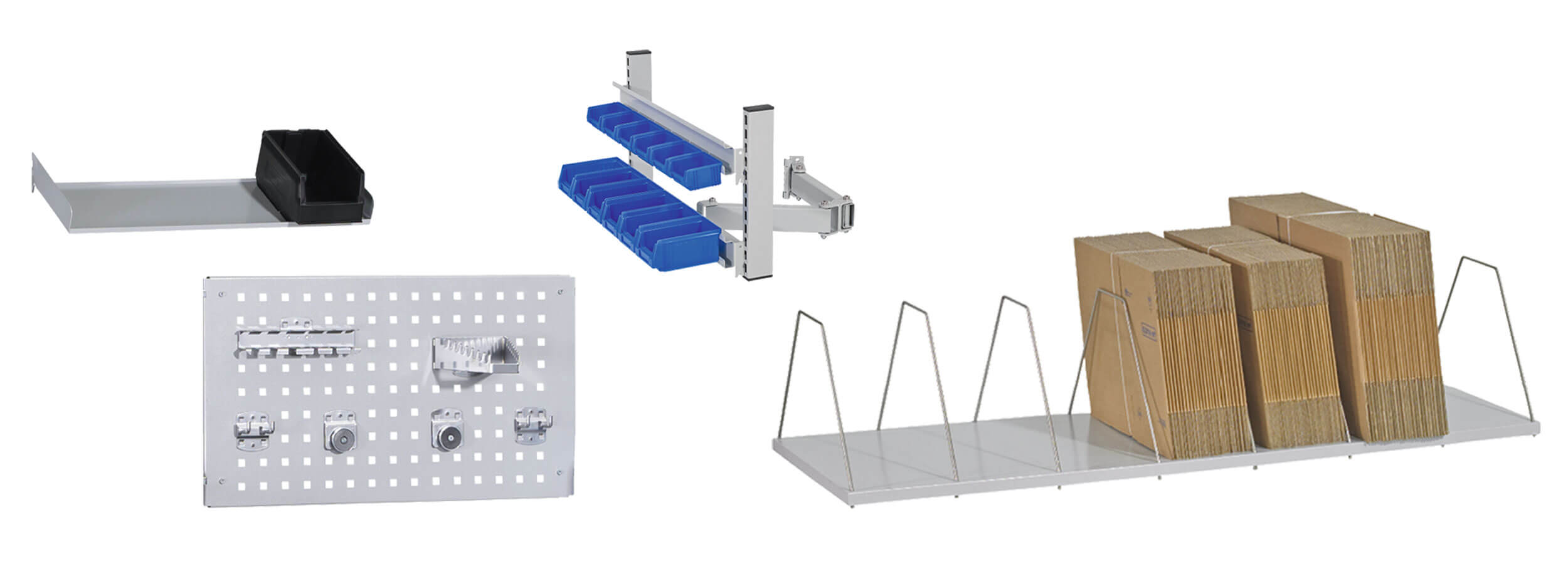

Discover ERGO-line packing tables: ideal for logistics and shipping. With our versatile modular system , the tables adapt precisely to your needs. Have special requirements? We’ll design a custom-made solution for you. With height adjustment and ergonomic design, you improve employee wellbeing and speed up your processes—effectively and sustainably.

Assembly tables

Hundreds of customers across Europe can vouch for our custom-tailored solutions.

We have one goal: to create a workstation that perfectly suits your needs. We fulfil most wishes with our extensive and modular building system. For specific individual cases, we provide

Goods receipt & goods inspection

- Universal tables

- Computer workstations

- Storage tables for printers

- Mail sorting tables

Manufacturing & Assembly

- Individual workstations

- ESD workstations

- Electronics workstations

- Measuring and testing workstations

- Workbenches

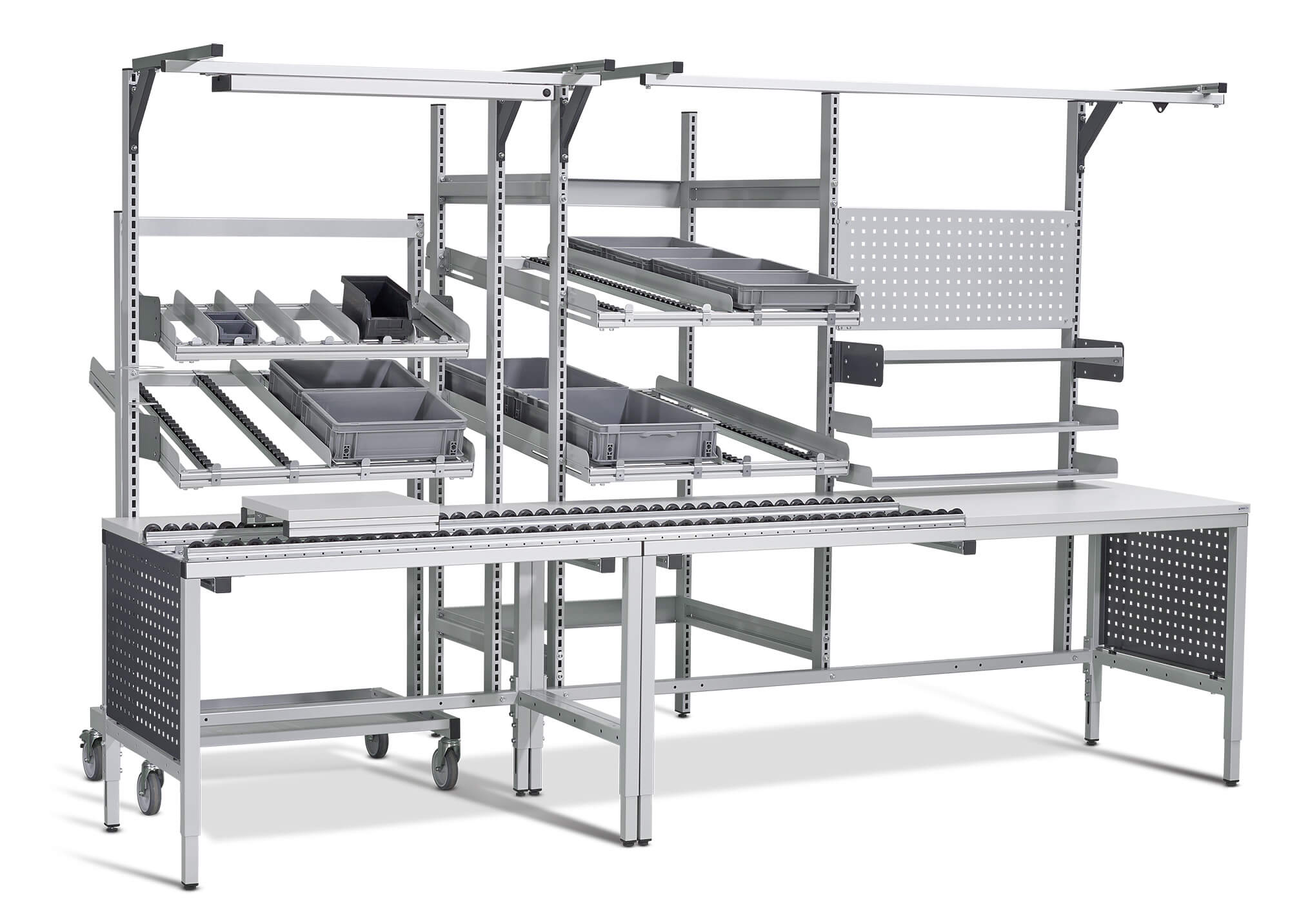

Flow of goods & material supply

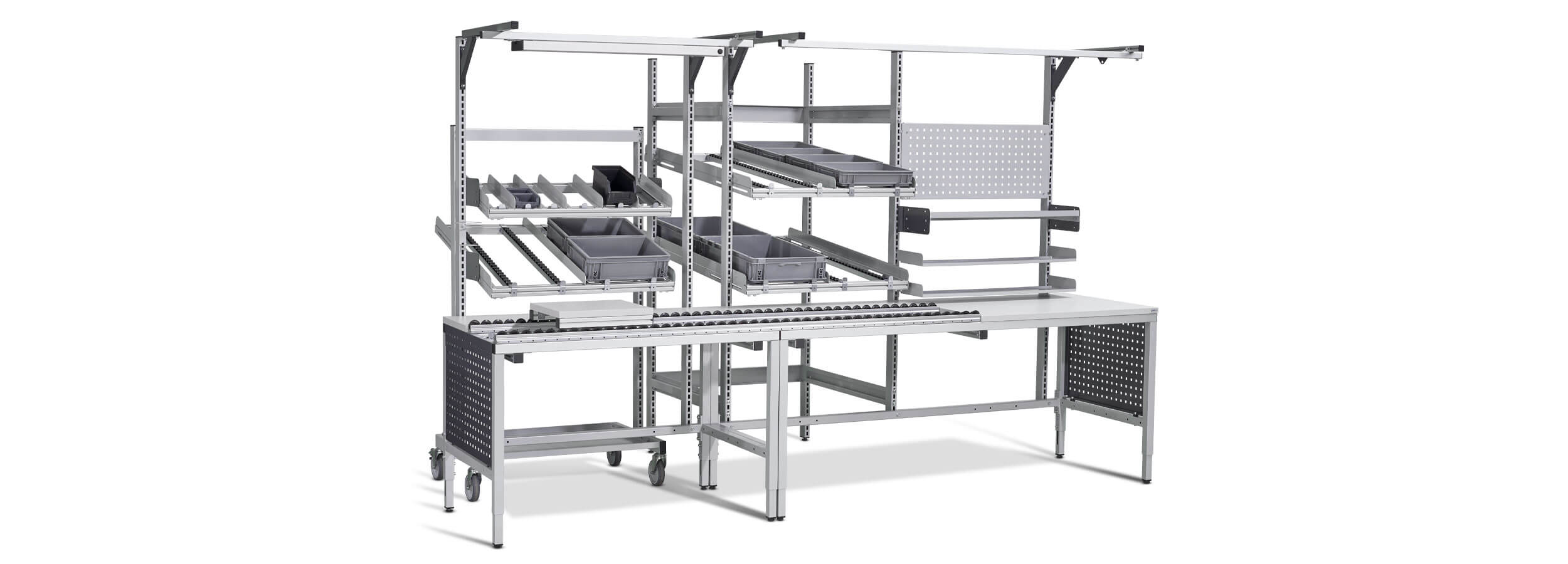

- Interlinked workstations

- Mobile workstations

- FIFO storage racks

- Freestanding attachments with perforated sheet metal

- Roller conveyors

- Transport carts

- Box and magazine carts

- Picking and storage carts

Shipping processing

- Simple packing tables

- Modular packing tables

- Packing tables with integrated filling systems

- Cutting tools

- Roller stands

References & Customer Testimonials

ESD tables

ESD tables for the maximum safety and quality of your electronics

ERGO-line tables are EU-certified for ESD protection. This reliably protects your electronics from electrostatic discharge and supports employee wellbeing through ergonomic design. And it’s not just our tables—much of our accessories range is also effectively protected against ESD damage. Build a workstation with long-lasting protection and deliver outstanding quality to your customers in every single component.

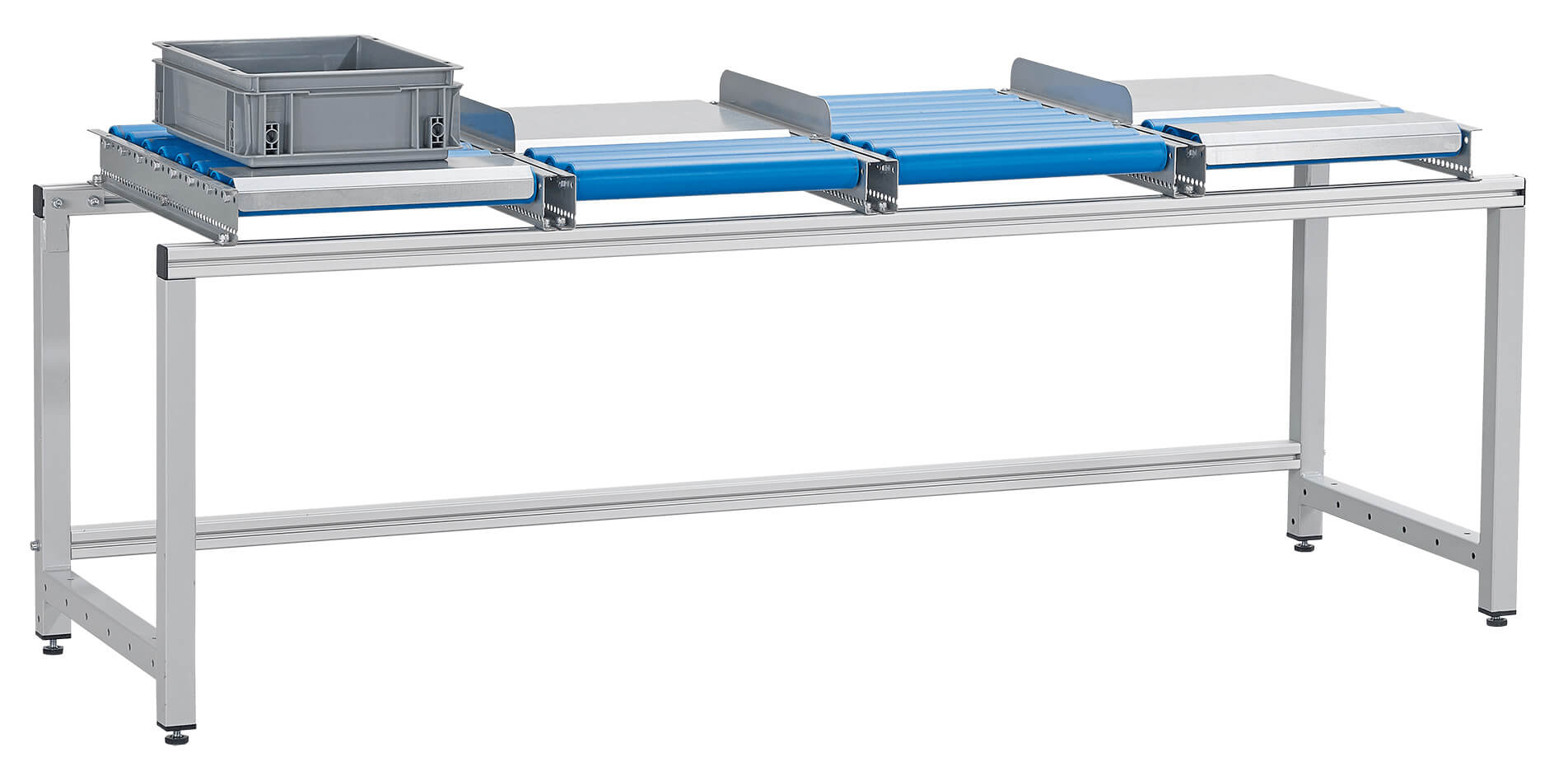

Assembly lines

Assembly lines for fast and efficient work processes

With our assembly lines, we enable efficient flow production for greater speed and quality. Use roller conveyors to easily combine multiple work steps. “Just-in-time” production is key: materials are provided exactly when you need them. Experience streamlined workflows, save valuable time, and achieve consistently excellent results.

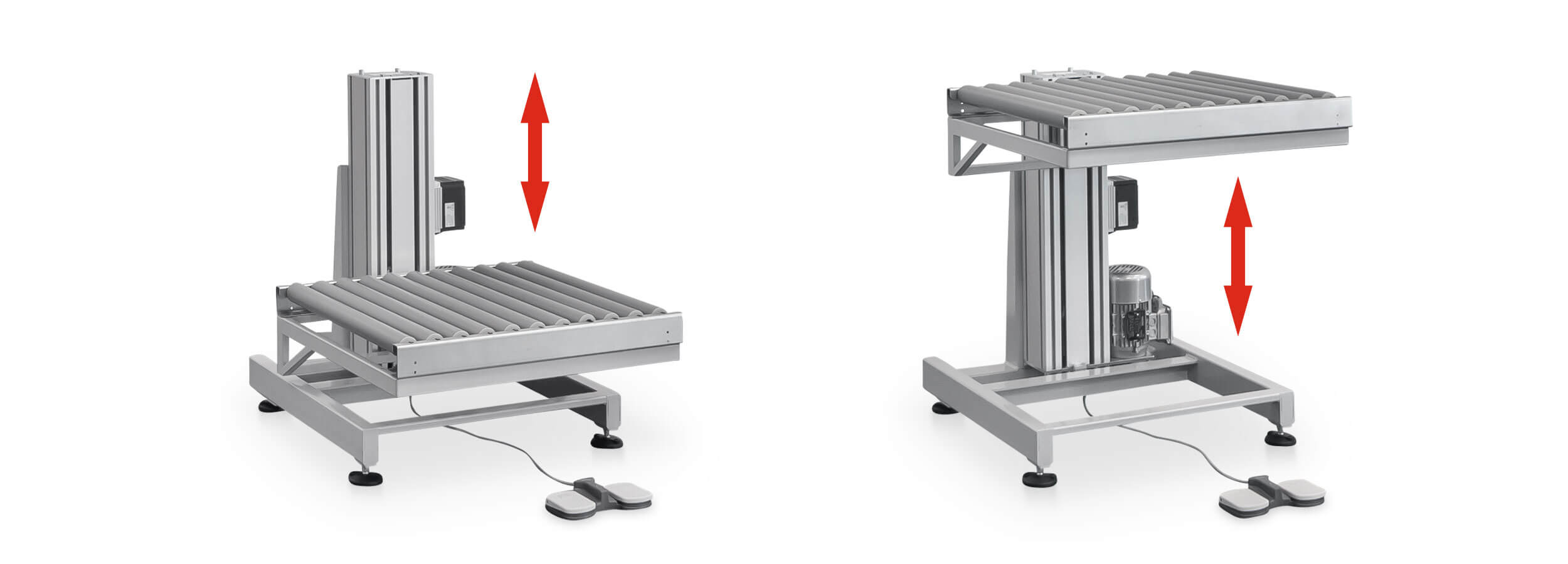

Assembly aids

Ergonomic assembly with less effort and greater precision

ERGO-line help you position heavy components—such as control cabinets and mounting plates—safely and flexibly. Thanks to continuous height and tilt adjustment, you create ergonomic working conditions with higher precision and less physical strain. This improves assembly quality while reducing the effort required from your team. Invest in ergonomic tools that speed up processes and deliver long-term relief.

3D Configurator

Configure your table in minutes

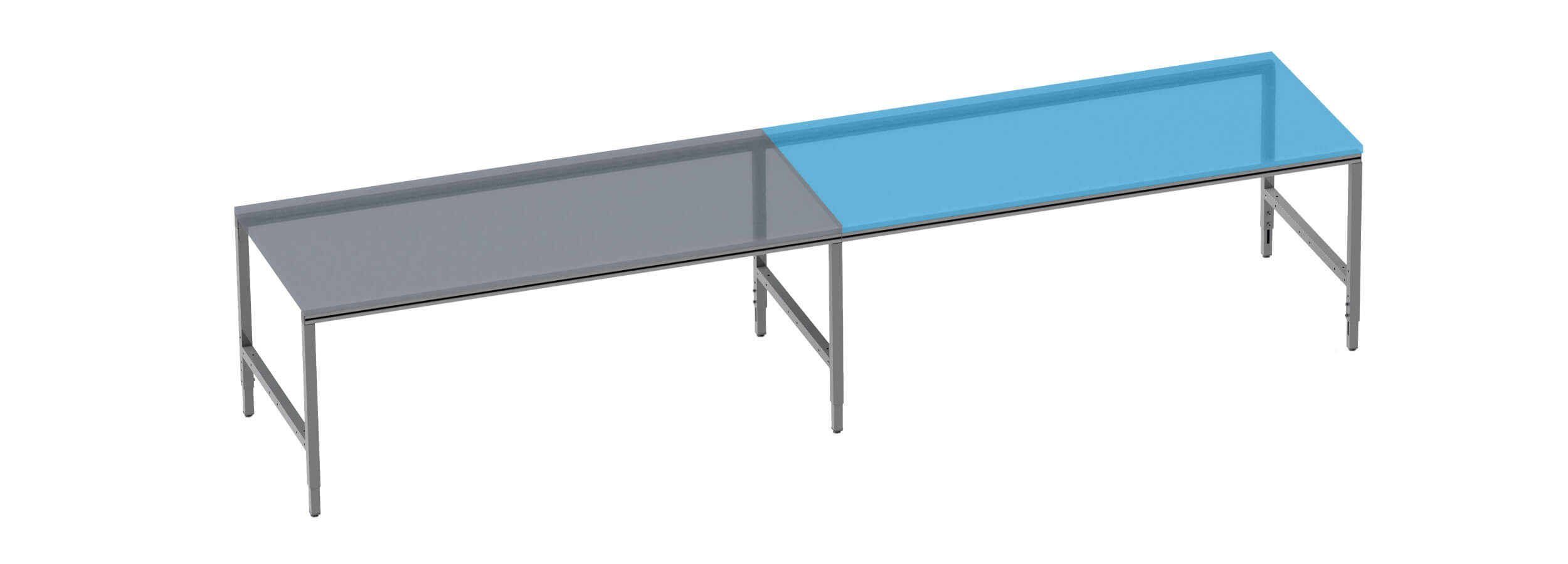

With ERGO-line, you can configure one or multiple tables yourself. First choose a table frame and outfit it with the right add-ons and accessories.

Hundreds of customers across Europe trust our made-to-measure solutions

We have one goal: to create a workstation that fits your requirements perfectly. Most needs are covered with our extensive modular system. For special one-off cases, we produce custom-made solutions tailored precisely to your needs. That’s how we deliver the right solution for every challenge. Hundreds of customers are already thrilled with their new customized work area—built around your exact requirements.

This is how your new workstation will be created

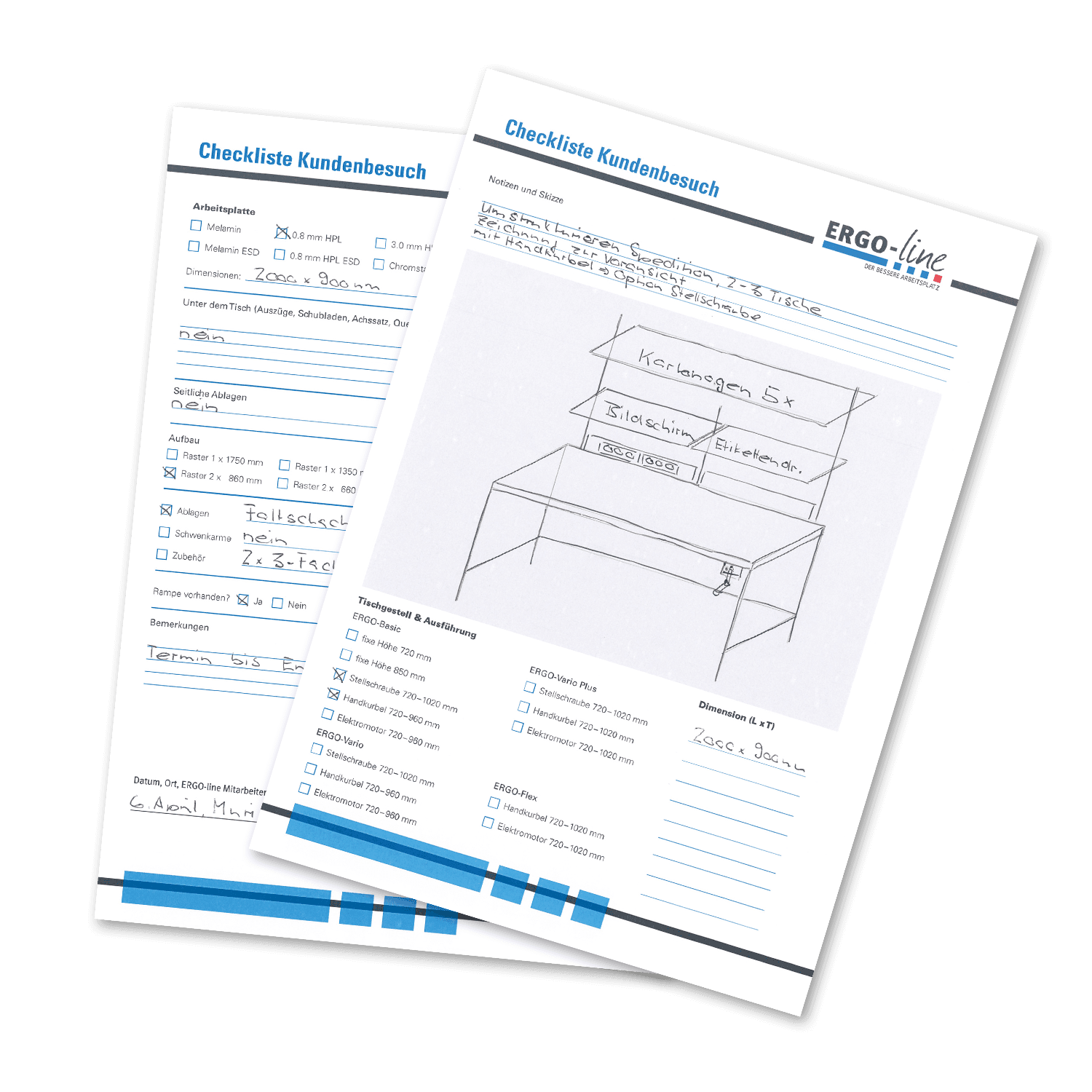

Initial Consultation

The ERGO line product portfolio is modular. This means every table can be set up exactly the way you need it. It can also be changed or expanded later. No matter what your workspace requires, ERGO line gives you a solution that helps your team work better, faster and more comfortable.

A modular system offers many choices. To keep things simple, we start with a free initial consultation. This helps us understand what you need and guide you to the best setup for your workspace.

Proposal & 3D Visualization

Through a focused analysis in the initial discussion, we identify your priorities and design a tailored solution within your budget.

A core part of this solution is a 3D visualization that digitally maps your exact space and layout. You get a clear picture of your future workflows and can fine-tune details as needed.

If we visit you on site, we can also show your new workstation in Augmented Reality. It shows your space and layout on the screen, so you can see what your future workspace will look like.

This makes it easy to adjust details before anything is built.

Rapid implementation, short lead times

From planning to a finished, ready-to-use solution, it often takes us just 4–6 weeks. If you’d like to handle installation yourself, each table arrives preassembled right off the truck. And if you’d rather not do the assembly, simply use our installation service. We’re happy to come on-site and set up your new workspace in no time.

For large projects, we build a sample table. This lets you test your workspace and make any final adjustments you need.

Request a consultation

ERGO-line workbenches adapt to your workflows and processes

No two companies are alike. No process is the same. That’s why our ERGO-line table frames are designed to be modular. Every frame is compatible with all tabletops and the matching, useful accessories. This lets you make adjustments quickly and without drilling whenever needed—and stay flexible for the long term.

What’s the best fit for your specific situation? We’re happy to figure it out together over the phone.

Further relevant questions about our workstation systems

What are the benefits of a modular workstation system?

Modular workstation systems adapt easily to different workflows, teams, and space constraints. They’re built from standardized components that can be combined or expanded. Components include shelving, lift modules, lighting, or IT integrations. The results are ergonomic, efficient workstations that grow with your needs. At ERGO-line, every system follows a thoughtful grid principle—ideal for companies planning for the future.

Which workbench is right for my operation?

The right choice depends on whether you work in shipping, assembly, or logistics. For high packing volumes, robust, height-adjustable systems with conveyor integration are best. Smaller operations often do well with compact solutions featuring core accessories. At ERGO-line, we configure your system exactly to your needs. Always modular and scalable.