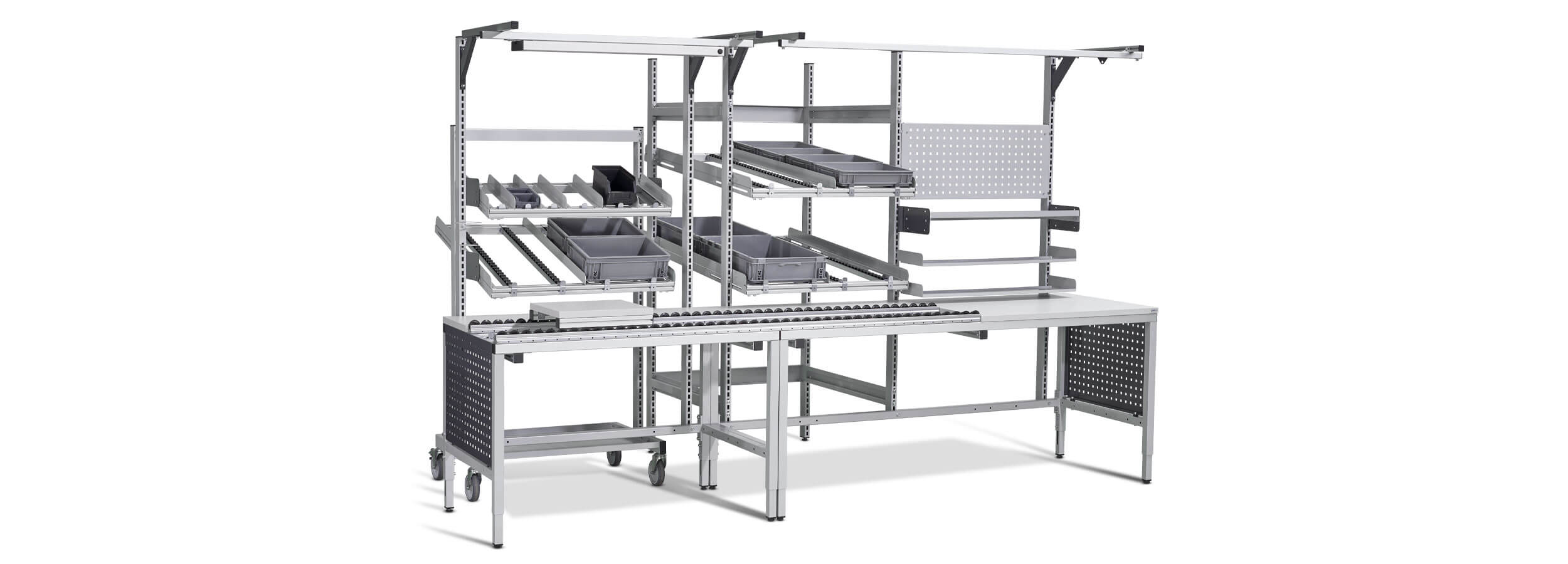

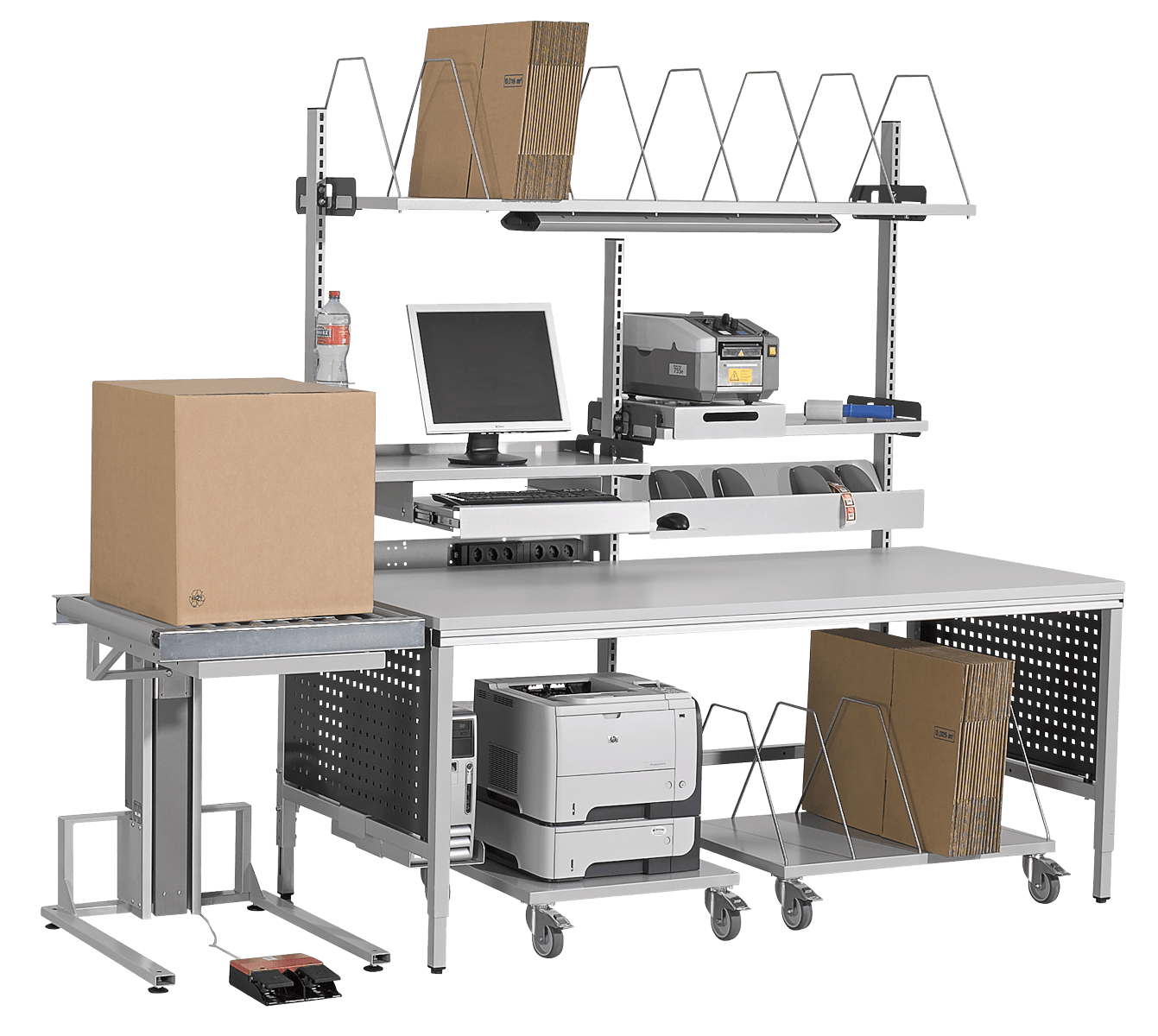

Workstation systems

Packing tables

Faster packing processes with ergonomic packing tables

ERGO-line packing tables sustainably optimise your logistics and shipping area. Benefit from height adjustability and ergonomic design – for improved employee health and faster work processes.

Fast. Simple. Effective.

Accelerated processes thanks to ergonomic packing stations

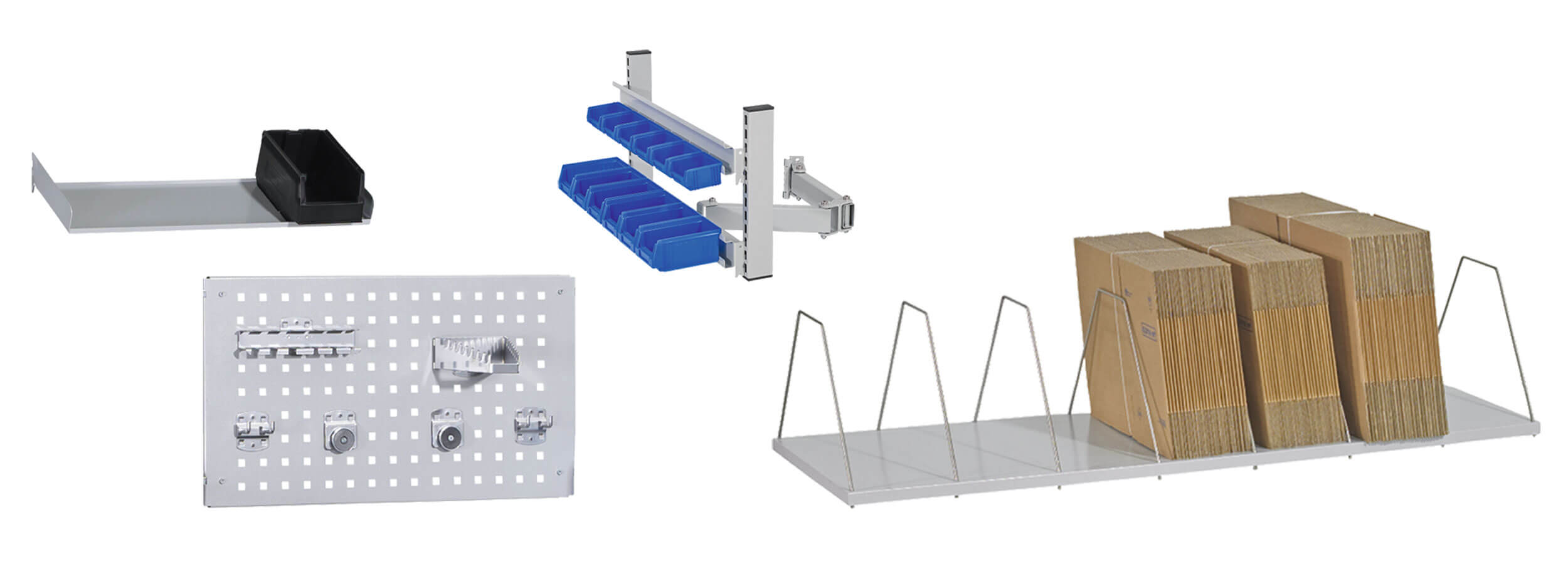

Our packing tables are optimised for efficient and ergonomic packing processes. Thanks to our simple modular system, the table can be individually adapted to your requirements. With its versatile accessories, integrated cutting devices, roller brackets for packaging materials and many other options, you can sustainably accelerate your work processes. Choose the right table and benefit from faster packing processes.

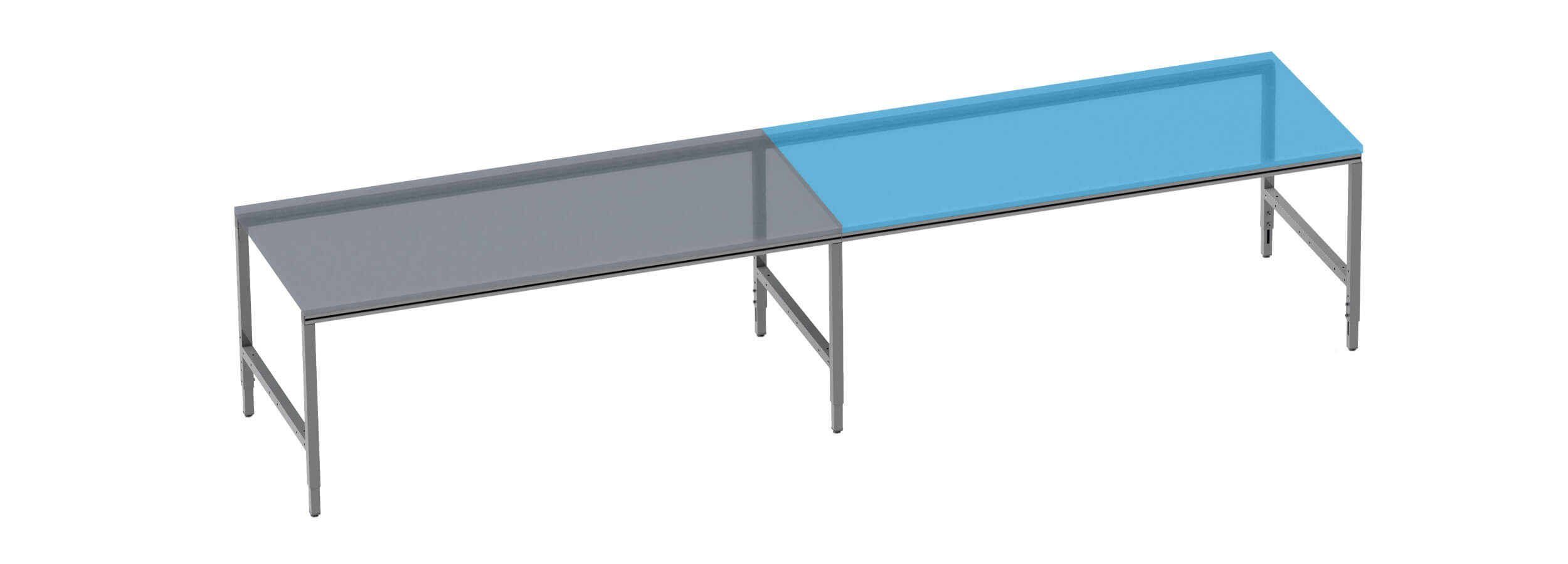

Start pre-configured - customise to your needs

Our pre-configured tables provide an ideal basis and are easy to customise in our 3D Configurator – from the features and dimensions to ergonomic additions.

3D Configurator

Configure your table in minutes

With ERGO-line, you can configure one or multiple tables yourself. First choose a table frame and outfit it with the right add-ons and accessories.

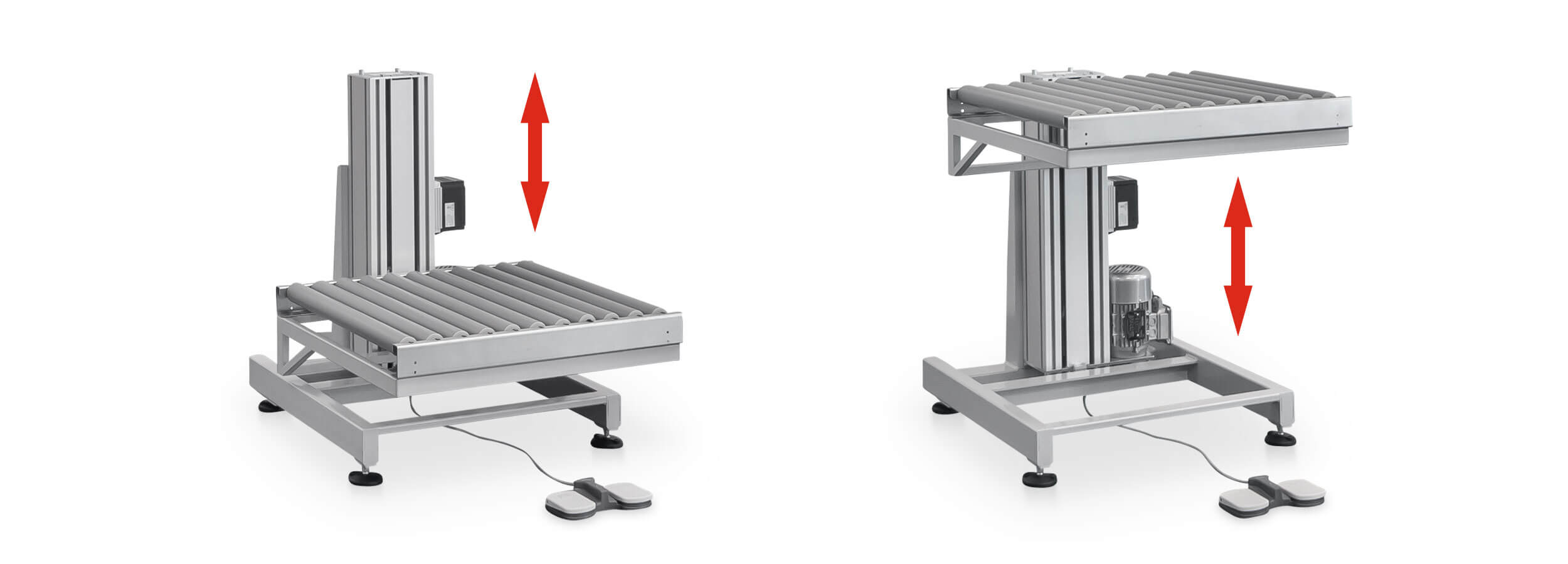

Packing tables for improved employee health

Our packing tables adapt flexibly to individual employee needs. With a clamping screw, hand crank, or electric motor, each workstation can be tailored to personalised requirements. Folding carton magazines and storage surfaces can be adjusted in 30:30 mm increments. Ergonomic optimisations demonstrably reduce working hours lost due to illness and increase your company's productivity.

Frequently Asked Questions (FAQ)

Which applications are ERGO-line packing tables ideal for?

Are ERGO-line packing tables a good fit for small businesses, too?

Can I customize my ERGO-line packing table?

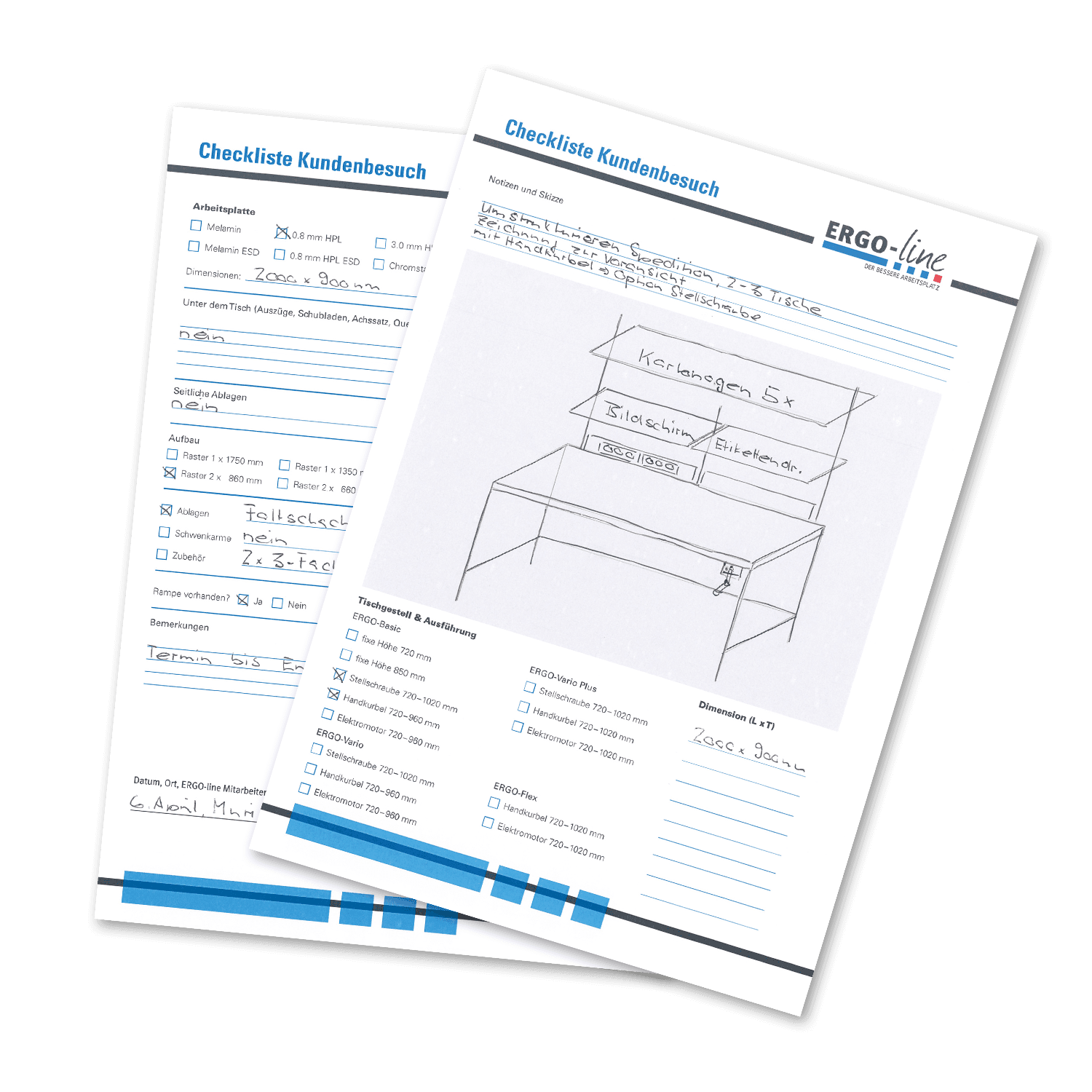

On-site consultation

Benefit from personal consultation by our specialist staff directly at your workplace. This allows us to get to know your individual requirements and demands in detail. Because we do not offer mass production: we find an individual solution for your specific situation and develop a suitable workstation system. We are happy to advise you directly on site. Alternatively, we can meet via video meeting or at our showroom, entirely according to your wishes.

3D visualizations

We digitalize your future workstation with 3D visualization

With our modern 3D visualizations, you can experience your future workstation even before installation. You receive a realistic representation that allows you to digitally review space requirements, work processes, and ergonomics in advance. This enables you to make adjustments and optimizations according to your wishes and achieve the perfect configuration for your requirements.

Custom solutions

Custom solutions for individual requirements

Thanks to the ERGO-line modular system, our configurations can be flexibly adapted to different working environments. We also develop suitable workstation systems for special requirements. Even for small quantities, we manufacture custom-made special solutions. These are compatible with our entire product range, allowing them to be easily expanded with our accessories.

Assembly service

We install your new workstation and train your employees

Our installation team professionally installs your new workstation system on site at your location. After setup, we provide comprehensive instruction to your team on operation and ergonomic benefits. This ensures that you and your employees benefit sustainably from the new workstation and fully utilize the potential of your new workstation system for faster packing processes and increased efficiency.

An ergonomic packing table promotes motivation, productivity, and efficiency.

Your packaging team spends the majority of their working time at the packing station. Therefore, this should be optimally designed – so that your employees are comfortable and remain productive.

Ideally, a packing table should integrate seamlessly into all packaging processes. This is what sets us apart at ERGO-line: We know that a bespoke workspace is essential. That’s why meticulous attention to detail and comprehensive consultation are our top priorities.

Our consultations are non-binding. With 3D visualisations, we ensure that our solution meets your requirements beforehand. With your help, many companies have already sustainably increased their productivity.

References & customer testimonials about our packing tables

ERGO-line packing tables – easily expandable even in 5 years

Our height-adjustable packing tables are designed according to a modular principle. Thanks to the modular system, our packing tables can still be easily expanded, adapted or redesigned five years from now – exactly according to your wishes.

We have the right accessories for every requirement, including integrated scales, air cushion systems, and conveyor technology. The ergonomic design ensures everything is quickly accessible, reducing potential errors and saving valuable time.

Perfect for warehousing and logistics – direct from the manufacturer

At ERGO-line, quality is our top priority. Our packing tables are made from high-quality materials and manufactured with precision. This ensures they remain robust and reliable even with intensive use over the long term.

We offer the right solution for every requirement: Whether with plastic coating, stainless steel or multiplex worktops, you can look forward to an ergonomic workstation of the highest quality that will make your packaging processes more efficient and sustainable.

Selection tool

Choose the right table frame for your needs

Our selection tool lets you see at a glance which table best suits your needs. For a fully configured packing table, ERGO-Budget offers the perfect solution. For customised configurations, we recommend our other table frames.

= Optimal

= Technically Feasible

| ERGO-Basic | ERGO-Vario | ERGO-Vario Plus | ERGO-Flex | ERGO-Forte | ERGO-Budget | ERGO-Light 2 | |

|---|---|---|---|---|---|---|---|

| Preconfigured Packing Table | |||||||

| Custom Packing Table | |||||||

| Heavy-Duty Packing Table | |||||||

| Single Workstation | |||||||

| Sit-Stand Workstation | |||||||

| Linked Workstations | |||||||

| ESD-Safe Work Tables | |||||||

| Mobile Tables | |||||||

| Custom Sizes |

= Optimal

= Technically Feasible

As individual as YOU

Discover the perfect accessories for your packing table frame

Customise your packing table to your liking. Thanks to our modular system, our entire product range is compatible with all table frames.

From planning to the finished packing table

Initial Consultation

The ERGO line product portfolio is modular. This means every table can be set up exactly the way you need it. It can also be changed or expanded later. No matter what your workspace requires, ERGO line gives you a solution that helps your team work better, faster and more comfortable.

A modular system offers many choices. To keep things simple, we start with a free initial consultation. This helps us understand what you need and guide you to the best setup for your workspace.

Proposal & 3D Visualization

Through a focused analysis in the initial discussion, we identify your priorities and design a tailored solution within your budget.

A core part of this solution is a 3D visualization that digitally maps your exact space and layout. You get a clear picture of your future workflows and can fine-tune details as needed.

If we visit you on site, we can also show your new workstation in Augmented Reality. It shows your space and layout on the screen, so you can see what your future workspace will look like.

This makes it easy to adjust details before anything is built.

Rapid implementation, short lead times

From planning to a finished, ready-to-use solution, it often takes us just 4–6 weeks. If you’d like to handle installation yourself, each table arrives preassembled right off the truck. And if you’d rather not do the assembly, simply use our installation service. We’re happy to come on-site and set up your new workspace in no time.

For large projects, we build a sample table. This lets you test your workspace and make any final adjustments you need.

Request a consultation

ERGO-line workbenches adapt to your workflows and processes

No two companies are alike. No process is the same. That’s why our ERGO-line table frames are designed to be modular. Every frame is compatible with all tabletops and the matching, useful accessories. This lets you make adjustments quickly and without drilling whenever needed—and stay flexible for the long term.

What’s the best fit for your specific situation? We’re happy to figure it out together over the phone.